Development of metal stamping shrapnel fasteners:

First, the variety is messy. The processing method has changed from the initial artificial factor to the increased degree of mechanization. From the manual modulation of the production process to the automation, fasteners can produce a variety of crafts and hardware accessories.

Second, the scale is relatively small, and the Chinese market is relatively flexible in terms of production methods, which can quickly meet market changes and needs, and can achieve rapid development in the short term, but the scale has become its development bottleneck.

Third, the products are low-end and the cost is relatively low. Most of the manufacturers of metal stamping shrapnel fasteners in China are private enterprises, and often the manufacturers are responsible for product technical monitoring, and sales also become part of their work. There is a certain gap between the management mechanism and operation mode of enterprises and relatively perfect enterprises.

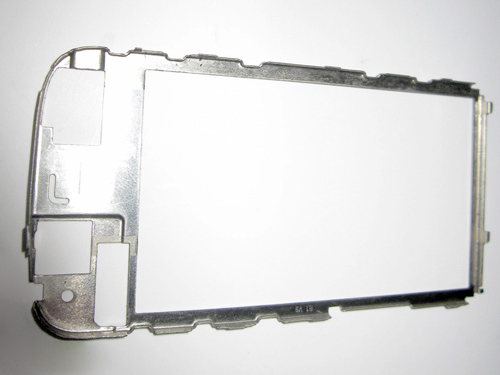

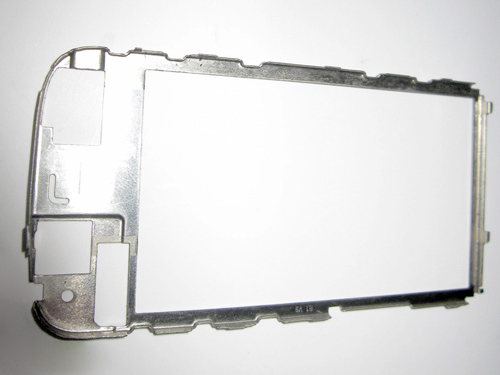

The production of metal shrapnel is a special process of processing materials (metal or non-metal) into parts (or semi-finished products) by cold stamping of stamping dies. Stamping is a pressure processing method that uses a die installed on a press to apply pressure to a material at room temperature to separate or plastically deform it to obtain the required parts.

In the stamping processing industry, there are only a few specialized machinery and equipment for manufacturing stamping shrapnel.